MENU

ID | IDR

ID | IDR

You are about to leave this site.

Please be aware that your current cart is not saved yet and cannot be restored on the new site nor when you come back. If you want to save your cart please login in into your account.

No results found

Search Suggestions

Water-jacketed incubators: Do they really provide a higher temperature uniformity for your cells?

Lab Academy

- Cell Biology

- Cell Culture

- Stem Cells

- Lab Routine

- Reproducibility

- CO2 Incubators

- Essay

In this article, we look at the questions whether or not water-jacketed incubators can really provide higher reproducibility of cell culture results.

This article was published first in "Inside Cell Culture" , the monthly newsletter for cell culture professionals. Find more interesting articles about CO2 incubators on our page "FAQs and material on CO2 incubators" .

Water-jacketed incubators have been traditionally chosen by cell culture labs with high demands regarding temperature uniformity and temperature stability during power outage. In our article series, we will analyze and evaluate the advantages and limitations of this incubator heat transfer technology and compare it to direct heat and air-jacketed incubators. In our last articles, we looked at the main disadvantages of water-jacketed incubators and the question of whether they can really hold the temperature longer during power outages and provide a higher relative humidity.

Surprisingly, an analysis of currently available incubators on the market has shown that the temperature uniformity of water-jacketed incubators is either equal to (±0.3 °C) or only 0.1 °C better (±0.2 °C) than direct heat or air-jacketed incubators. Therefore, given significant disadvantages of the technology, like missing high temperature disinfection, it is advisable to compare devices and estimate the potential impact of a 0.1 °C lower temperature uniformity on the individual cell culture experiment planned. To our knowledge, there is no published systematic analysis on the effect of temperature in this range.

In contrast to temperature uniformity, other incubator-inherent properties may be more likely to affect experimental reproducibility. For example, the impact of a circulating fan or air coming from a fan duct opening on cultures on the top shelf needs to be considered. Furthermore, one also needs to keep in mind when comparing different incubators that there are various methods/standards to evaluate the temperature uniformity. Amongst these standards, the DIN 12880:2007-05 standard (“Electrical laboratory devices - Heating ovens and incubators”) using 27 temperature sensors (nine per incubator shelf) is the strictest and can be used as a valuable tool to directly compare different models.

Introduction

Water-jacketed incubators have been traditionally chosen by cell culture labs with high demands regarding temperature uniformity and temperature stability during power outage. In our article series, we will analyze and evaluate the advantages and limitations of this incubator heat transfer technology and compare it to direct heat and air-jacketed incubators. In our last articles, we looked at the main disadvantages of water-jacketed incubators and the question of whether they can really hold the temperature longer during power outages and provide a higher relative humidity.

Do water-jacketed incubators provide a higher temperature uniformity?

Surprisingly, an analysis of currently available incubators on the market has shown that the temperature uniformity of water-jacketed incubators is either equal to (±0.3 °C) or only 0.1 °C better (±0.2 °C) than direct heat or air-jacketed incubators. Therefore, given significant disadvantages of the technology, like missing high temperature disinfection, it is advisable to compare devices and estimate the potential impact of a 0.1 °C lower temperature uniformity on the individual cell culture experiment planned. To our knowledge, there is no published systematic analysis on the effect of temperature in this range.

Other important factors influencing reproducibility

In contrast to temperature uniformity, other incubator-inherent properties may be more likely to affect experimental reproducibility. For example, the impact of a circulating fan or air coming from a fan duct opening on cultures on the top shelf needs to be considered. Furthermore, one also needs to keep in mind when comparing different incubators that there are various methods/standards to evaluate the temperature uniformity. Amongst these standards, the DIN 12880:2007-05 standard (“Electrical laboratory devices - Heating ovens and incubators”) using 27 temperature sensors (nine per incubator shelf) is the strictest and can be used as a valuable tool to directly compare different models.

Read more

Read less

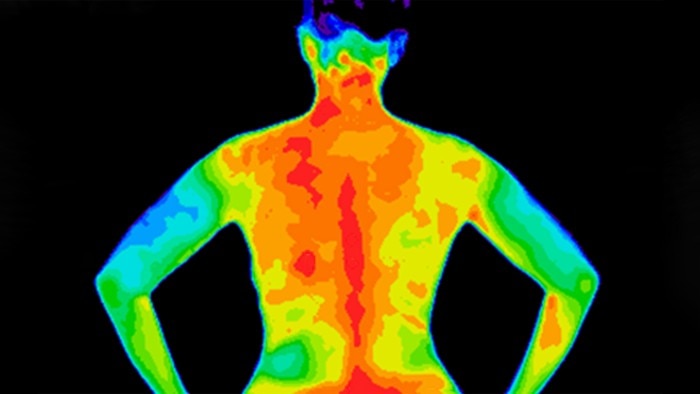

Figure 1: Measurement set-up according to DIN 12880:2007-05 – 27 temperature probes placed at different locations on three shelves inside the CO2 incubator

Read more

Read less

Interested in other helpful articles related to selecting, handling, or maintaining CO2 incubators?

Read more

Read less